AEROSPACE

Anderson Group’s CNC machinery plays a critical and expanding role in the manufacturing of aerospace equipment, meeting the industry's stringent demands for precision, reliability, and the ability to process advanced materials.

From its Focaseiki metalwork-focussed range to the broader Anderson Group CNC machinery, they provide precision machining of complex components and processing of advanced materials - lightweight yet durable.

They also play an essential role in rapid prototyping, allowing engineers to quickly create functional models for design evaluation before full-scale production.

-

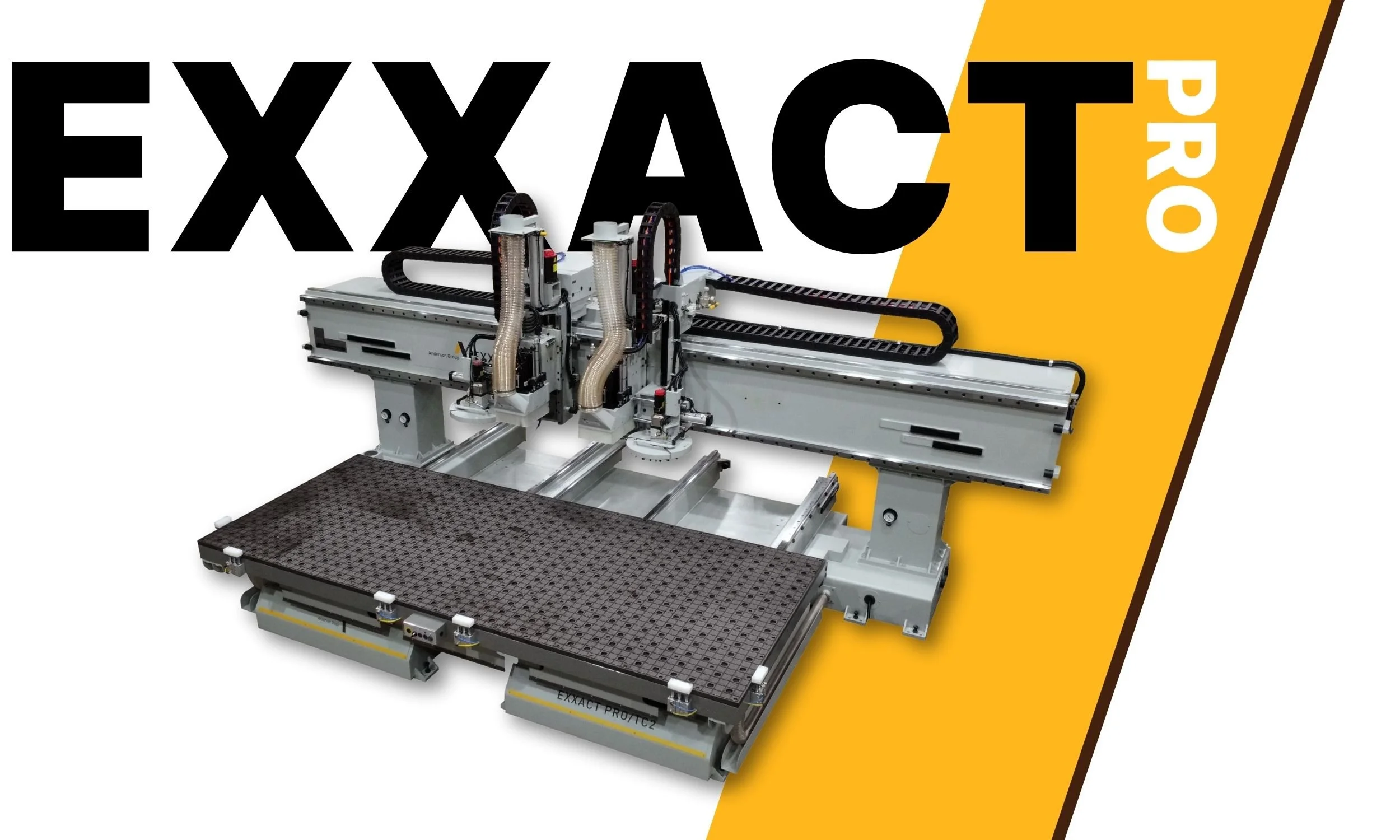

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

-

✔️ Furniture & Cabinetry

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ Cutting & Routing

✔️ Drilling & Boring

✔️ Automation (DUO)

-

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

-

✔️ Furniture & Cabinetry

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ Cutting & Routing

✔️ Drilling & Boring

✔️ Automation (DUO)

-

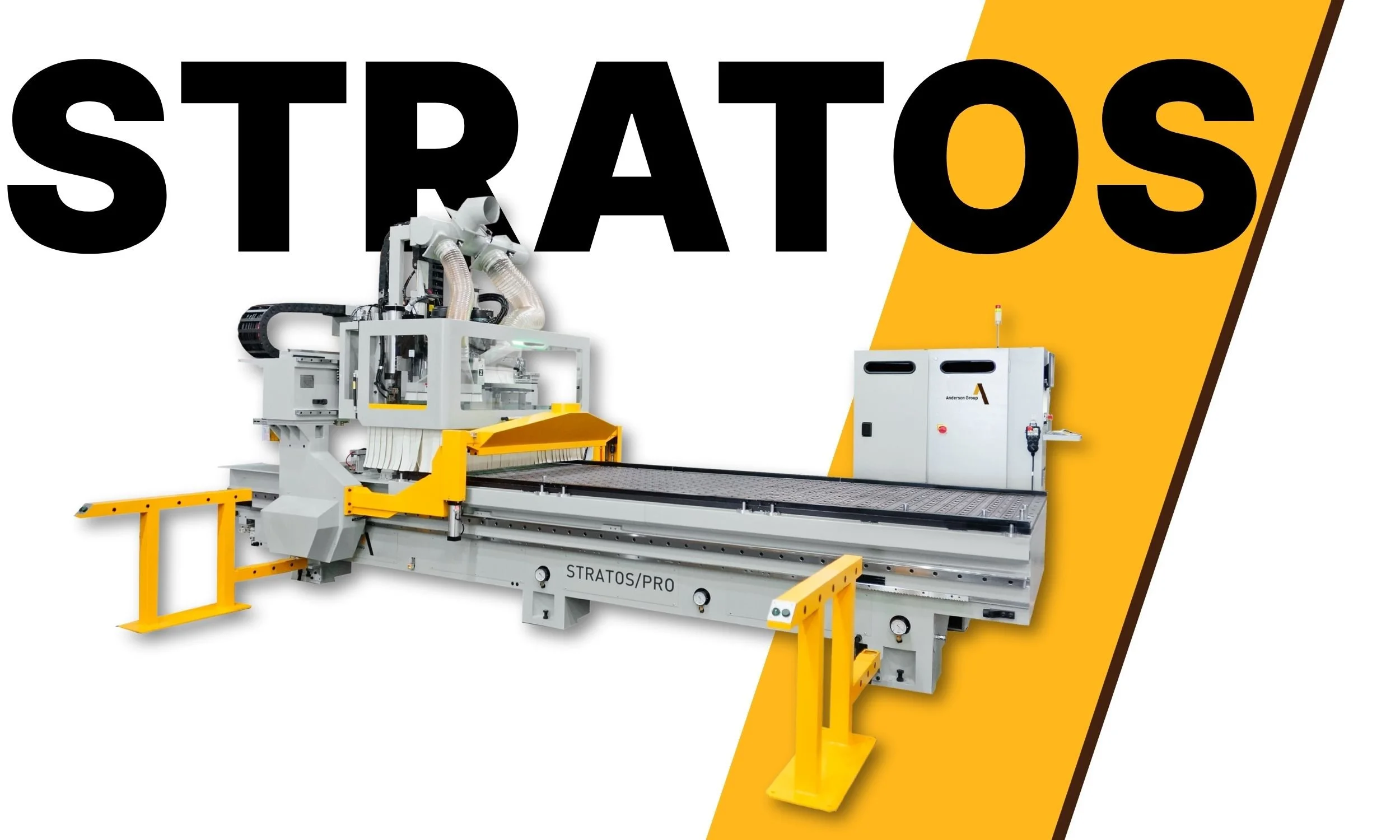

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ 5 Axis Machining

✔️ Large Format Materials

✔️ Cutting & Routing

✔️ Drilling & Boring

-

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ 5 Axis Machining

✔️ Retractable Roof Design

✔️ Advanced Dust Collection

✔️ Cutting & Routing

✔️ Drilling & Boring

-

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ 5 Axis Machining

✔️ Advanced Automation

✔️ Cutting & Routing

✔️ Drilling & Boring

-

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

✔️ Panel Processing

-

✔️ Furniture & Cabinetry

-

✔️ Cutting & Routing

✔️ Drilling & Boring

✔️ Automation Ready

-

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

✔️ Panel Processing

-

✔️ Furniture & Cabinetry

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ Cutting & Routing

✔️ Drilling & Boring

✔️ Automation

✔️ Workpiece Holding

-

✔️ Non-Ferrous Metal

✔️ Advanced Materials

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ 5 Axis Machining

✔️ Cutting & Routing

✔️ Drilling & Boring

✔️ Automation

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Drilling & Tapping

✔️ Compact Design

✔️ Speed & Precision

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Drilling & Tapping

✔️ Integrated APC

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Vertical Machining

✔️ Heavy Loading

✔️ High Precision

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Vertical Machining

✔️ Large Scale Workpieces

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Vertical Machining

✔️ Heavy Loading

✔️ Fast Cycle Times

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Vertical Machining

✔️ Integrated APC

✔️ High Volume

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Vertical Machining

✔️ Boxway Guides

✔️ Powerful Spindle

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Vertical Machining

✔️ Integrated APC

✔️ High Volume

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Double Column

✔️ Box-type Construction

✔️ Powerful Spindle

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ 5-Axis Control

✔️ Compact Footprint

✔️ High Precision

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ 5-Axis Control

✔️ Ram-type Moving Column

✔️ High-Speed Spindle

-

✔️ Zero-Point Clampers

✔️ Multi-Pallet Capacity

✔️ Small Footprint

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering