• NON-FERROUS METALS •

• FERROUS METALS •

• NON-FERROUS METALS •

• FERROUS METALS •

• NON-FERROUS METALS • • FERROUS METALS • • NON-FERROUS METALS • • FERROUS METALS •

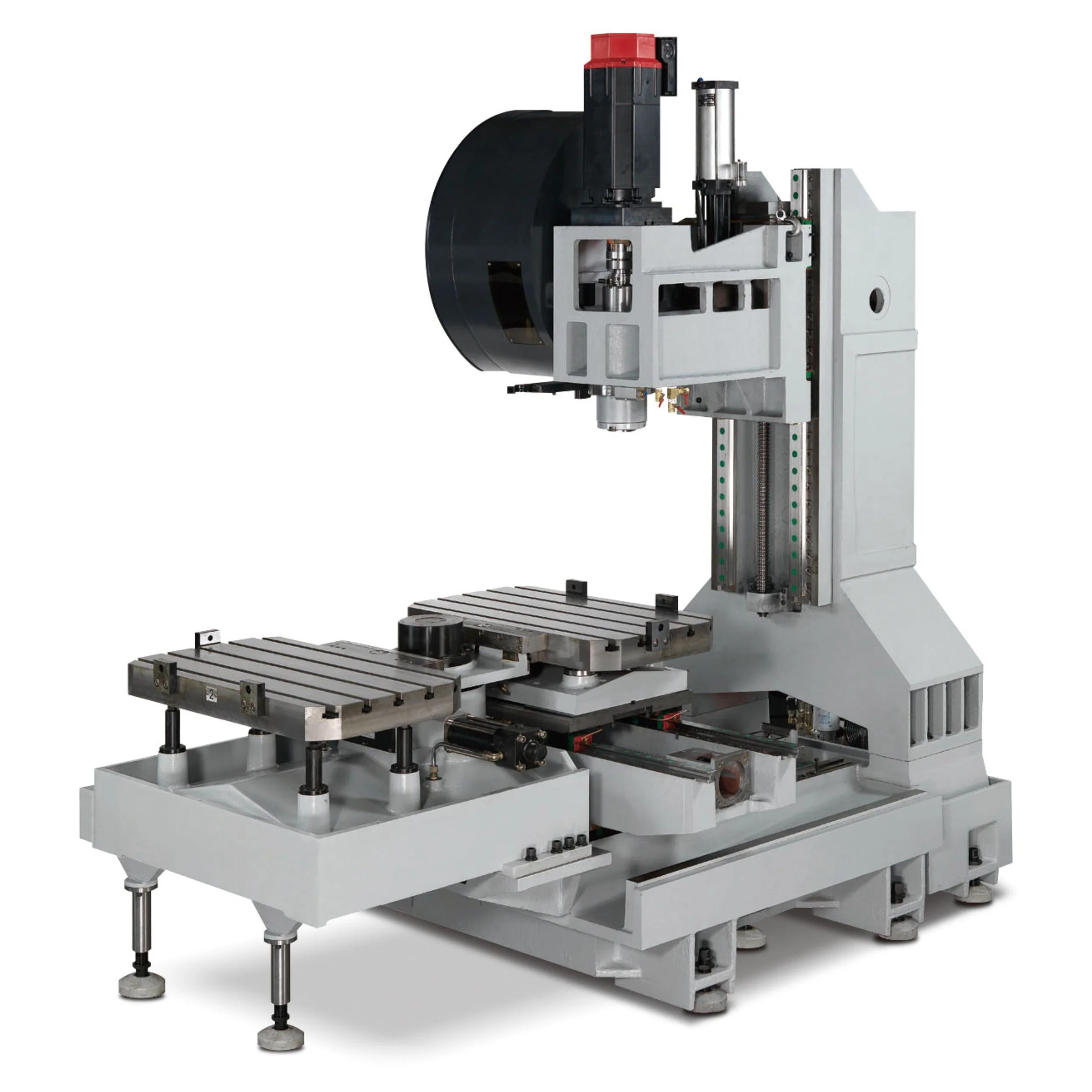

Automate Your Success With The VMC-600APC | 860APC | 1100APC Vertical Machining Centres With APC.

The Focaseiki VMC-600APC | 860APC | 1100APC Vertical Machining Centres with APC are designed for high-volume production, eliminating downtime through their Automatic Pallet Changer (APC). They are engineered for higher stability and continuous, uninterrupted operation, enhancing productivity and efficiency.

Key features:

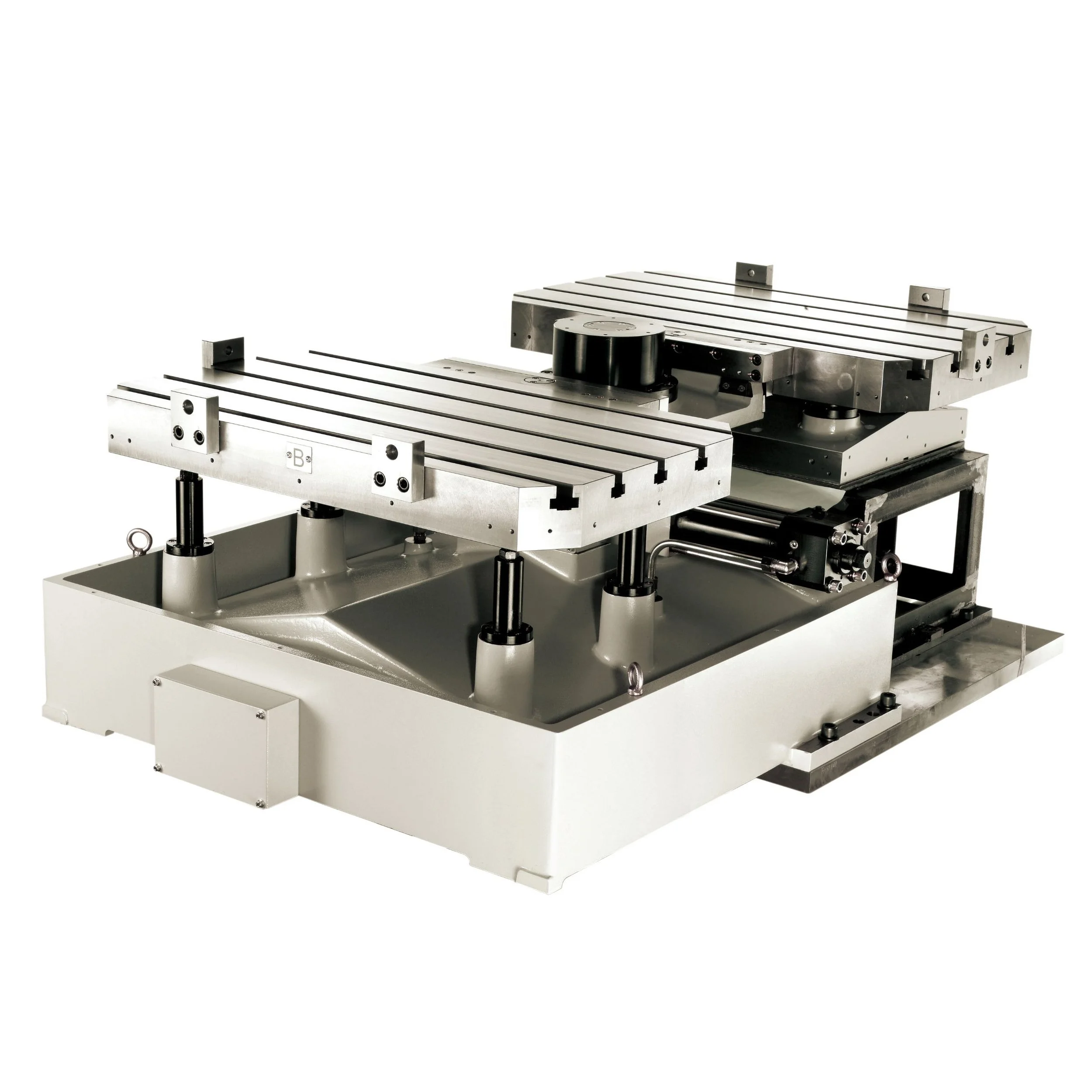

Automatic Pallet Changer (APC): This core feature allows for continuous production by enabling the operator to load and unload a new workpiece on one pallet while the machine is actively machining on the other. The pallet change cycle time is 7 ± 1 seconds.

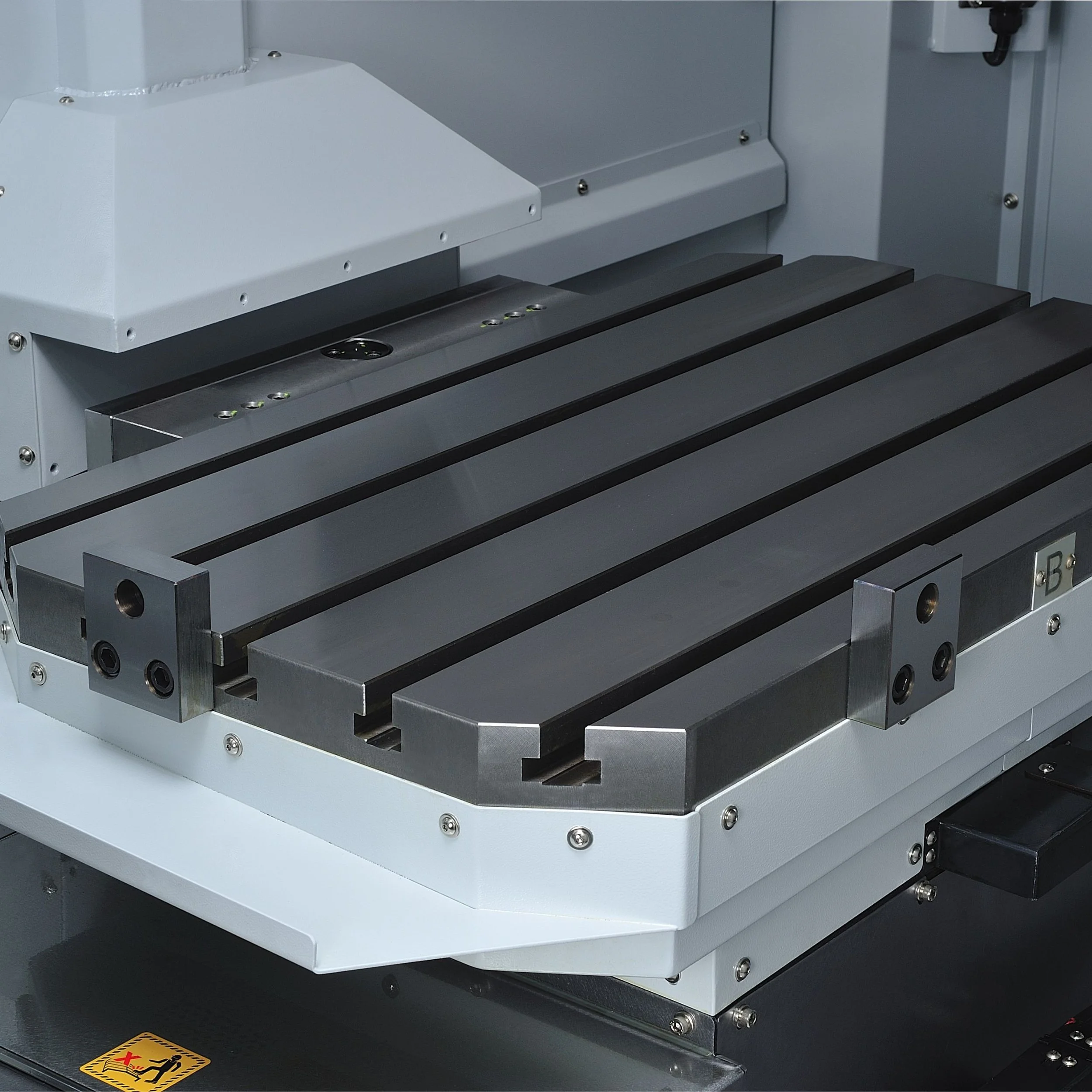

High Rigidity and Stability: The machines are built with an extra-wide base and eight levelling bolts for high stability and to avoid deformation. The X, Y, and Z axes utilise high-rigidity roller-type linear guideways.

Enhanced Chip Management: The APC series includes a chip conveyor to enhance productivity, and the base and APC have a slant design to facilitate easy chip flushing and prevent chips from adhering to the structure.

Hydraulic Pallet Clamping: The Automatic Pallet Changer uses a hydraulic clamping system with a clamp force of 50 kg/cm² for a secure and stable workpiece setup.

Spindle Cooling Device: These VMCs are equipped with a direct-type spindle motor cooling device to maintain temperature stability and ensure consistent performance during long machining cycles.

Video & Photos

SPECIFICATIONS:

| MODEL: | VMC-600APC | VMC-860APC | VMC-1100APC |

|---|---|---|---|

| Table Size (mm) | 660x500 | 850x500 | 1000x500 |

| X/Y/Z Travel (mm) | 610/480/500 | 860/560/600 | 1100/560/600 |

| Spindle (RPM) | ISO-40:10000/12000/15000 | ISO-40:8000/10000/12000/15000 ISO-50:6000/8000/10000 |

|

| ATC (T) | ISO-40:24/30 | ISO-40:24/30/36 ISO-50:20/24 |

|

| Rapid Feed Rate (M/min) | 36/36/36 | 36/36/30(48/48/36) | 30/30/24(36/36/30) |

| Guide Way | Roller Type Linear Guides | ||