AUTOMOTIVE

Anderson Group’s CNC machines play a significant role in the manufacturing of automotive equipment by providing the precision, efficiency, and material versatility required for modern production.

From its Focaseiki metalwork-focussed range to the broader Anderson Group CNC machinery, they provide precision machining of complex components and processing of advanced materials - lightweight yet durable. Their high accuracy and consistency adhere to rigorous industry quality and safety standards.

They also play an essential role in rapid prototyping, allowing engineers to quickly create functional models for design evaluation before full-scale production.

-

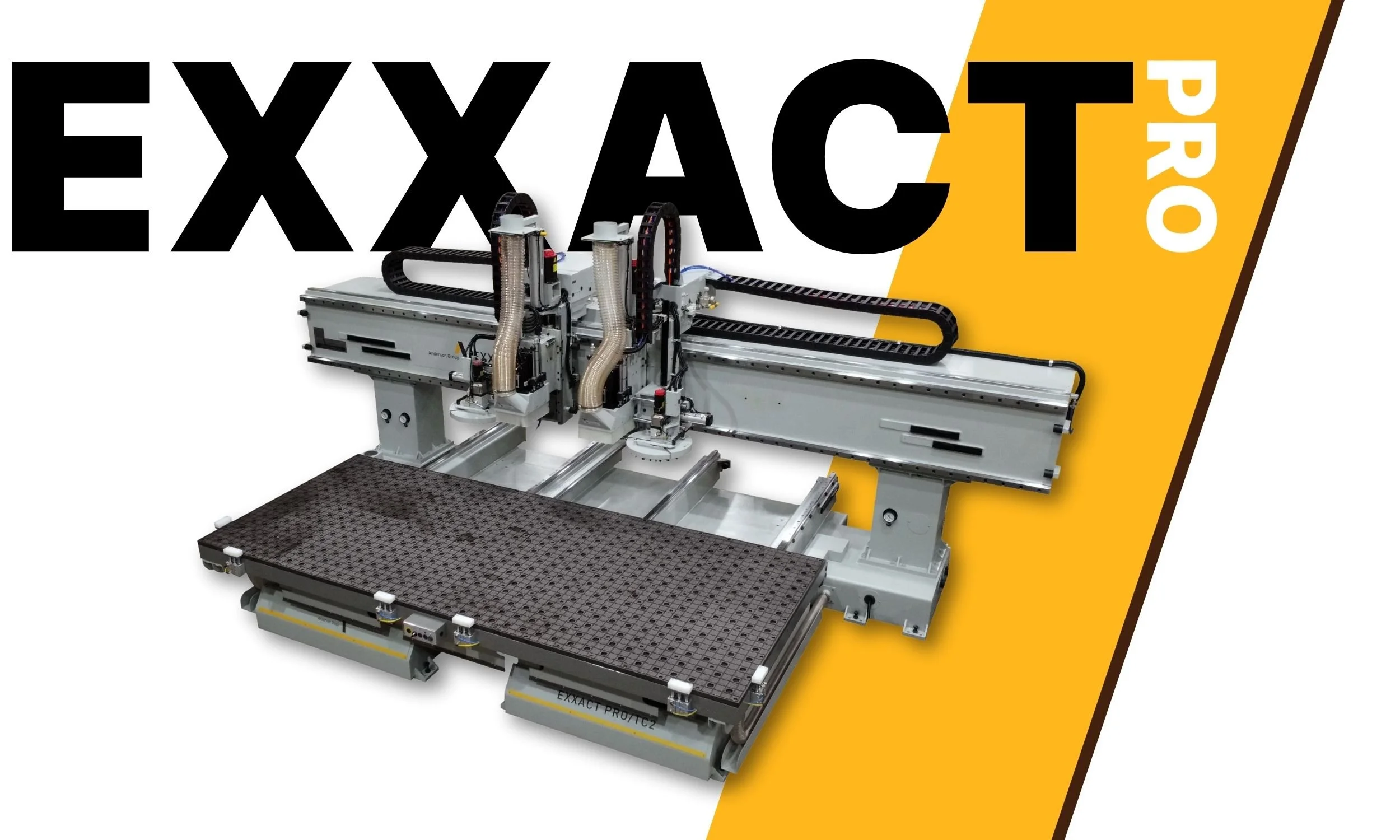

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

-

✔️ Furniture & Cabinetry

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ Cutting & Routing

✔️ Drilling & Boring

✔️ Automation (DUO)

-

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

-

✔️ Furniture & Cabinetry

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ Cutting & Routing

✔️ Drilling & Boring

✔️ Automation (DUO)

-

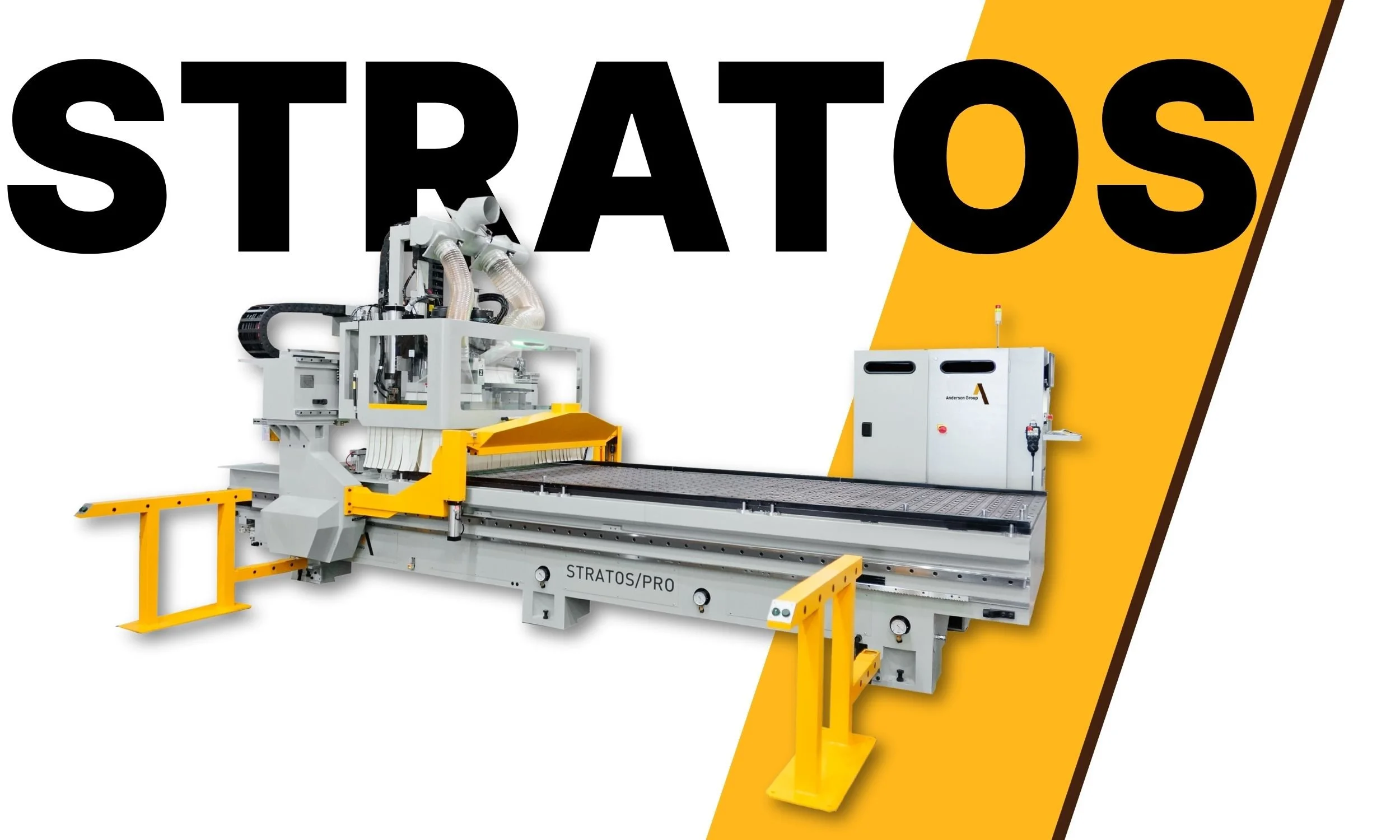

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ 5 Axis Machining

✔️ Large Format Materials

✔️ Cutting & Routing

✔️ Drilling & Boring

-

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ 5 Axis Machining

✔️ Retractable Roof Design

✔️ Advanced Dust Collection

✔️ Cutting & Routing

✔️ Drilling & Boring

-

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ 5 Axis Machining

✔️ Advanced Automation

✔️ Cutting & Routing

✔️ Drilling & Boring

-

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

✔️ Panel Processing

-

✔️ Furniture & Cabinetry

-

✔️ Cutting & Routing

✔️ Drilling & Boring

✔️ Automation Ready

-

✔️ Wood

✔️ Non-Ferrous Metal

✔️ Advanced Materials

✔️ Panel Processing

-

✔️ Furniture & Cabinetry

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ Cutting & Routing

✔️ Drilling & Boring

✔️ Automation

✔️ Workpiece Holding

-

✔️ Non-Ferrous Metal

✔️ Advanced Materials

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

-

✔️ 5 Axis Machining

✔️ Cutting & Routing

✔️ Drilling & Boring

✔️ Automation

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Drilling & Tapping

✔️ Compact Design

✔️ Speed & Precision

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Drilling & Tapping

✔️ Integrated APC

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Vertical Machining

✔️ Heavy Loading

✔️ High Precision

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Vertical Machining

✔️ Large Scale Workpieces

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Vertical Machining

✔️ Heavy Loading

✔️ Fast Cycle Times

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Vertical Machining

✔️ Integrated APC

✔️ High Volume

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Vertical Machining

✔️ Boxway Guides

✔️ Powerful Spindle

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Vertical Machining

✔️ Integrated APC

✔️ High Volume

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ Double Column

✔️ Box-type Construction

✔️ Powerful Spindle

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ 5-Axis Control

✔️ Compact Footprint

✔️ High Precision

-

✔️ Non-Ferrous Metals

✔️ Ferrous Metals

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering

-

✔️ 5-Axis Control

✔️ Ram-type Moving Column

✔️ High-Speed Spindle

-

✔️ Zero-Point Clampers

✔️ Multi-Pallet Capacity

✔️ Small Footprint

-

✔️ Aerospace

✔️ Automotive

✔️ Marine

✔️ General Engineering