• FERROUS METALS •

• NON-FERROUS METALS •

• FERROUS METALS •

• NON-FERROUS METALS •

• FERROUS METALS • • NON-FERROUS METALS • • FERROUS METALS • • NON-FERROUS METALS •

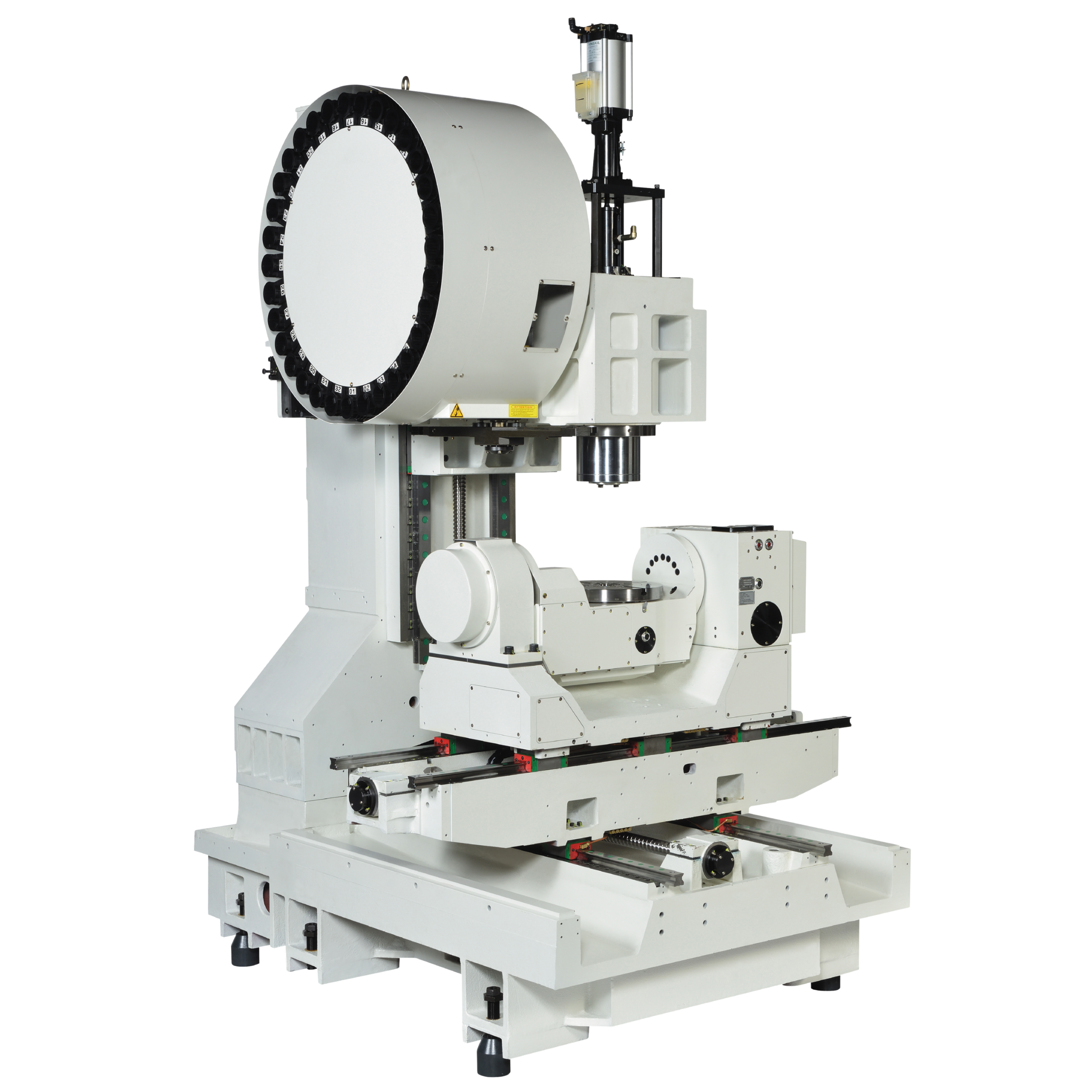

Go Beyond 3-Axis Limitations. Introducing the Focaseiki 5-Axis Vertical Machining Centre series.

The Focaseiki 5-Axis Vertical Machining Centre is a multi-functional machine capable of 3+2, 4+1, and simultaneous 5-axis machining. It combines a compact footprint with a large travel area, making it ideal for complex, high-precision part production.

Key features:

5-Axis Control: The machines are specifically designed for 5-axis control, including 3+2 and 4+1, as well as simultaneous 5-axis machining.

High-Precision Rotary Table: The rotary table features an external encoder for high positioning accuracy of 0.001 degrees, with an optional 5-second arc precision available.

Built-in Spindle as Standard: The machines come standard with a high-speed, built-in spindle, with speeds available up to 24,000 RPM as an option.

Space-Saving Design: This series has a small footprint but a large travel range, which allows for significant machining capacity without taking up excessive floor space.

Roller-Type Linear Guideways: All three linear axes (X, Y, and Z) are equipped with roller-type linear guideways, providing high rigidity and smooth motion.

Photos

SPECIFICATIONS:

| MODEL: | FUV-170 | FUV-200 | FUV-250 | FUV-320 | FUV-400 | FUV-500 |

|---|---|---|---|---|---|---|

| Table Size (mm) | Ø170 | Ø200 | Ø255 | Ø320 | Ø400 | Ø500 |

| X/Y/Z Travel (mm) | 360/470/515 | 360/450/495 | 360/440/515 | 460/500/500 | 460/500/500 | 600/700/500 |

| Spindle (Direct Type) | ISO-40:12000/15000 | ISO-40:10000/12000/15000 | ||||

| ATC (T) | ISO-40:24/30/36 | ISO-40:24/30/40 | ||||

| Rapid Feed Rate (M/min) | 36/36/36 | 36/36/30 | ||||

| Guide Way | Roller Type Linear Guides | |||||