• ADVANCED MATERIALS •

• NON-FERROUS METALS •

• WOODS •

• PLASTICS •

• ADVANCED MATERIALS • • NON-FERROUS METALS • • WOODS • • PLASTICS •

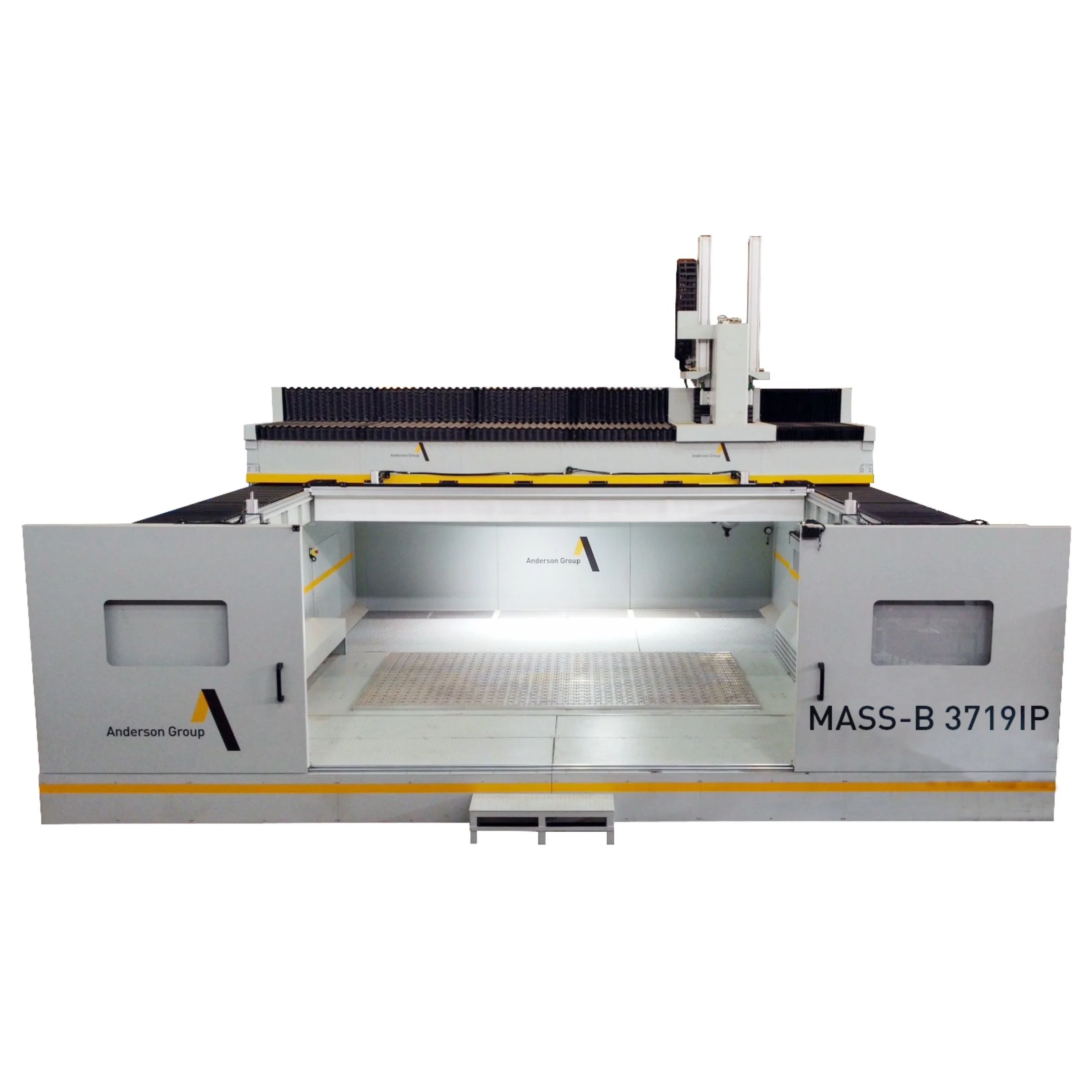

Beyond your expectations. Meet The Enclosed 5-Axis MASS-B CNC Centre.

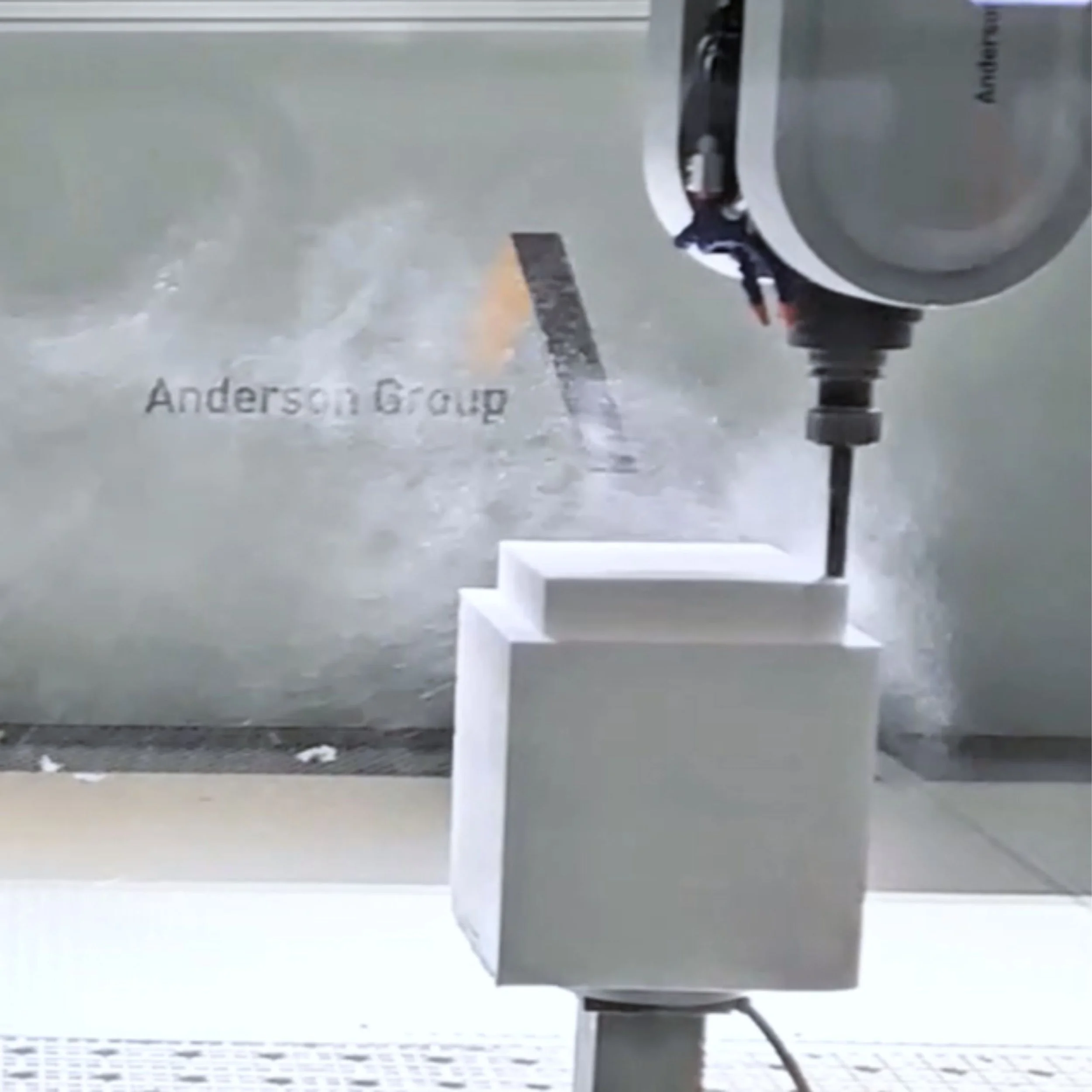

The MASS-B CNC Centre is an enclosed 5-axis machine specifically designed for efficient, high-precision processing of composites, advanced, and non-ferrous materials. It features a unique retractable roof for flexible operation, a powerful 26 HP liquid-cooled spindle, and advanced dust collection and tool measurement systems.

Key features:

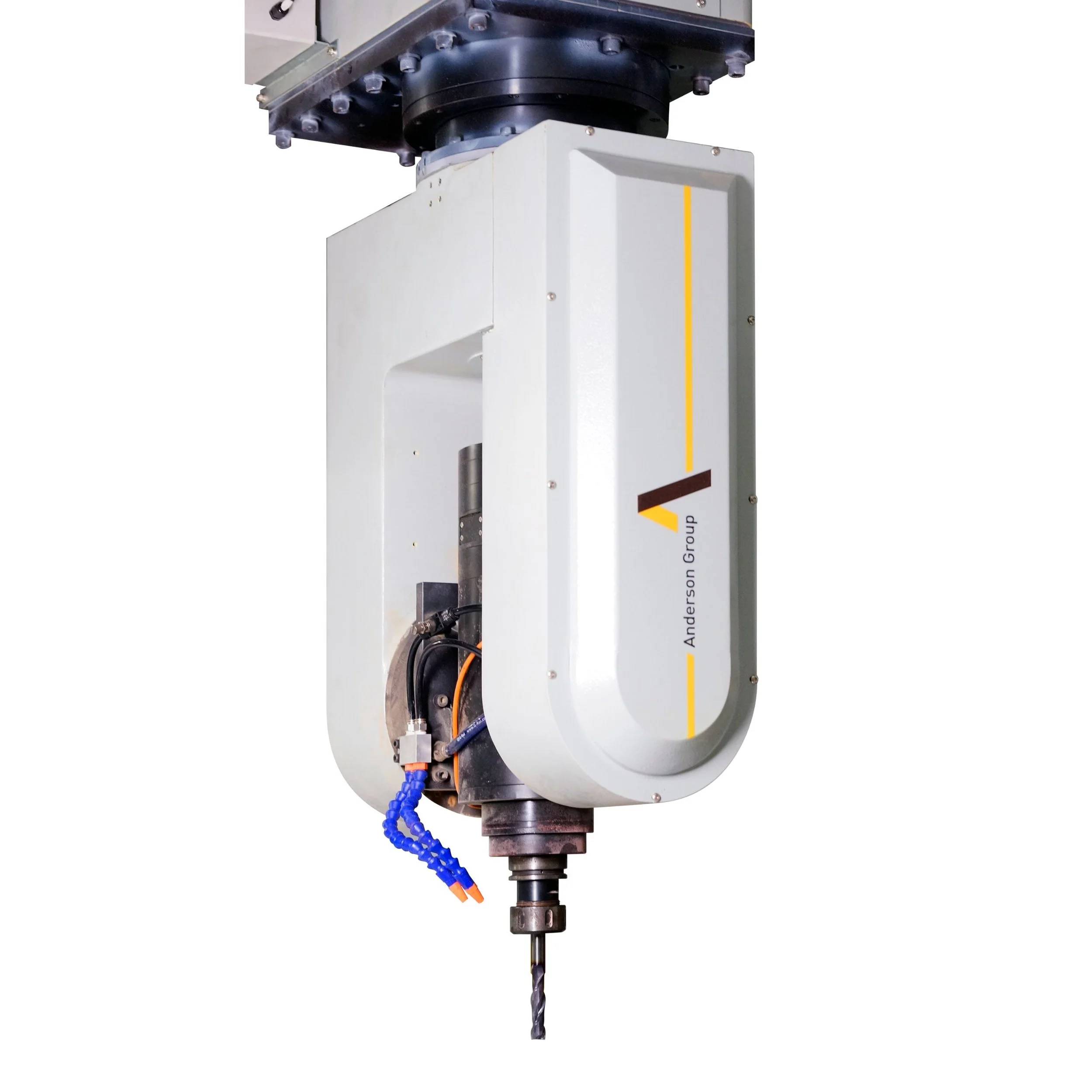

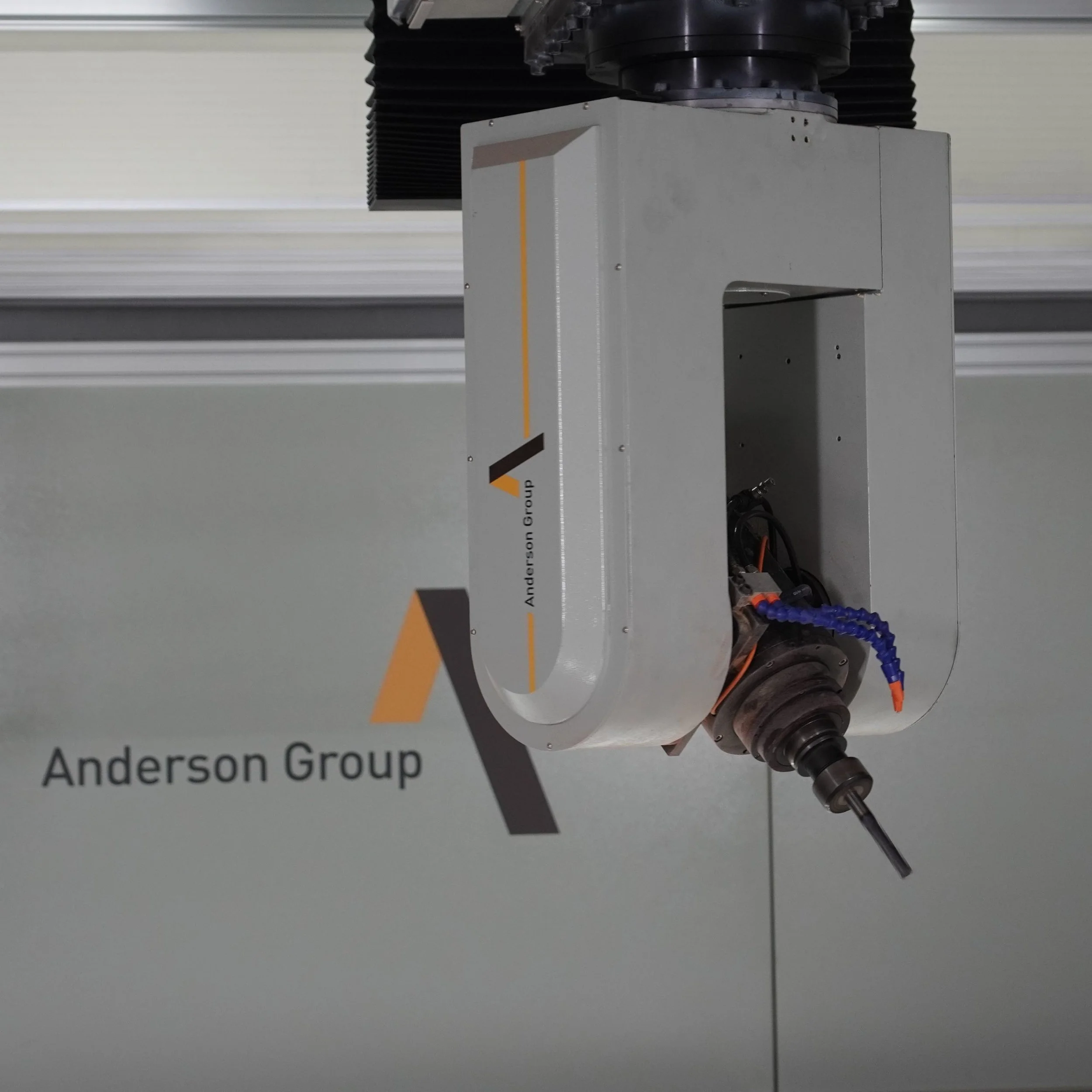

Enclosed 5-Axis Design: A highly advanced 5-axis CNC centre, specifically engineered for precision.

Specialised Material Processing: Designed for efficient processing of composite, advanced, and non-ferrous materials.

Retractable Roof: Features a unique, large retractable roof, enabling flexible operation between an enclosed and open workspace.

Powerful Liquid-Cooled Spindle: Equipped with a robust 26 HP liquid-cooled DC spindle for high output and demanding tasks.

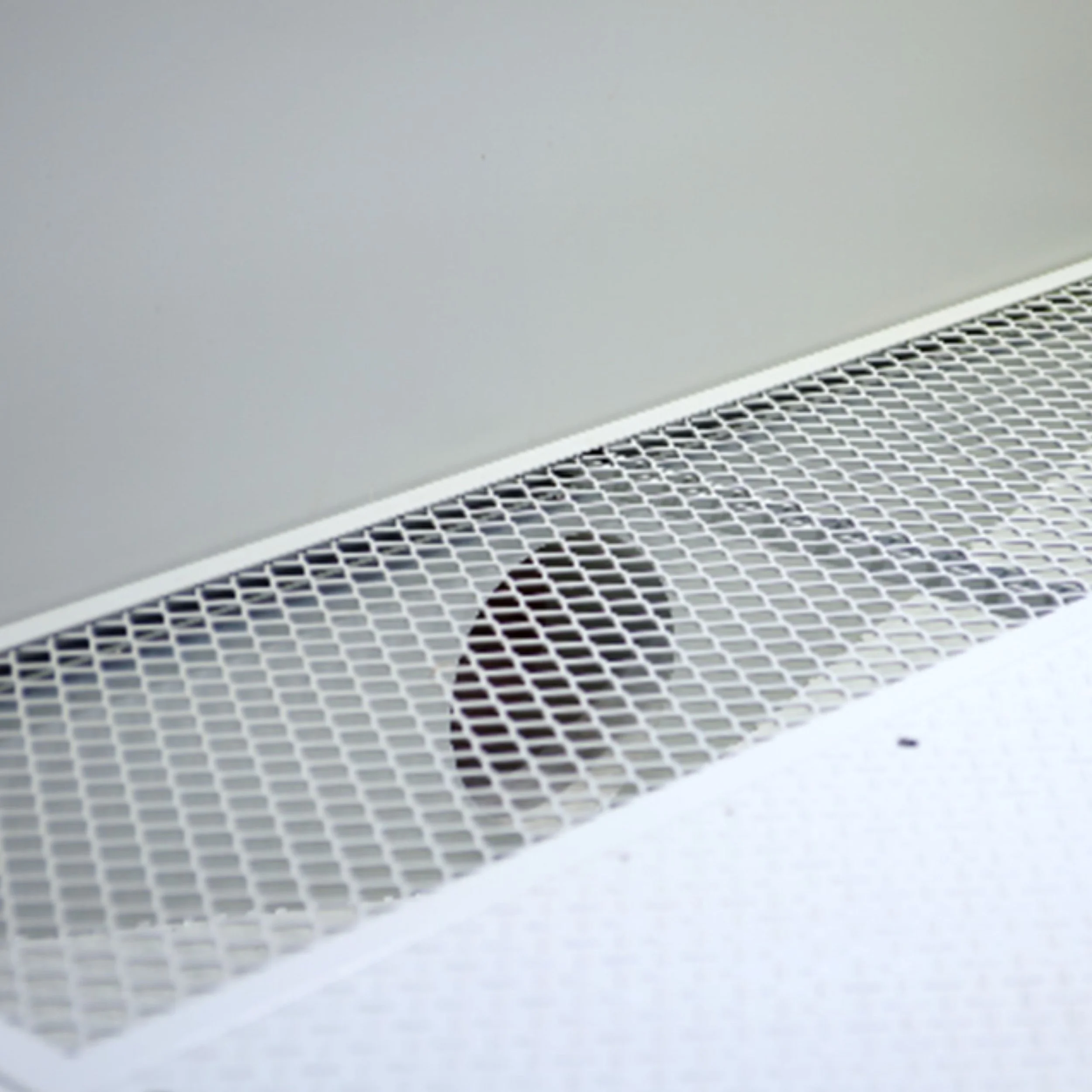

Advanced Dust Collection: Incorporates a specially designed push-pull flow field for highly effective dust collection and internal cleaning.

Automated Tool Management & Measurement: Offers a substantial 40-tool capacity across two 20-position carousels and integrates the Renishaw TS-27R measuring system for automatic tool specification measurement.

Videos & Photos

SPECIFICATIONS:

| MODEL: | MASS-B 3719IP | |

|---|---|---|

| APPLICATION | Non-Ferrous Metals, Composites | |

| STROKE | X AXIS | 3700 mm |

| Y AXIS | 2850 mm | |

| Z AXIS | 1200 mm | |

| B AXIS | ± 105。 | |

| C AXIS | ± 200。 | |

| TABLE SIZE | 3700 x1900 mm | |

| MAX FEED SPEED | XY AXIS | 60 m/min |

| Z AXIS | 20 m/min | |

| B,C AXIS | 90。/sec | |

|

ATC HEAD WITH

CAROUSEL

MAGAZINE

|

NO. OF SPINDLES | 1 |

| TOOL HOLDER SHANK | HSK-63F | |

| NUMBER OF TOOLS | 20 x 2 | |

| SPEED | 1,000~21,000 rpm | |

| TOOL DIMENSION | FOR ROUTER BIT(O.D.) | MAX.Ø25mm |

| POWER | ATC ROUTER | 20 kW x1 |

| AIR PRESSURE | 6 kg/cm | |

| NC CONTROLLER | FANUC 31i-MB5 | |

| DIMENSIONS | FLOOR AREA | 7700 x 6500 mm |

| HEIGHT | 5000 mm | |

| WEIGHT | 28000 kg | |