• ADVANCED MATERIALS •

• NON-FERROUS METALS •

• PLASTICS •

• WOODS •

• ADVANCED MATERIALS • • NON-FERROUS METALS • • PLASTICS • • WOODS •

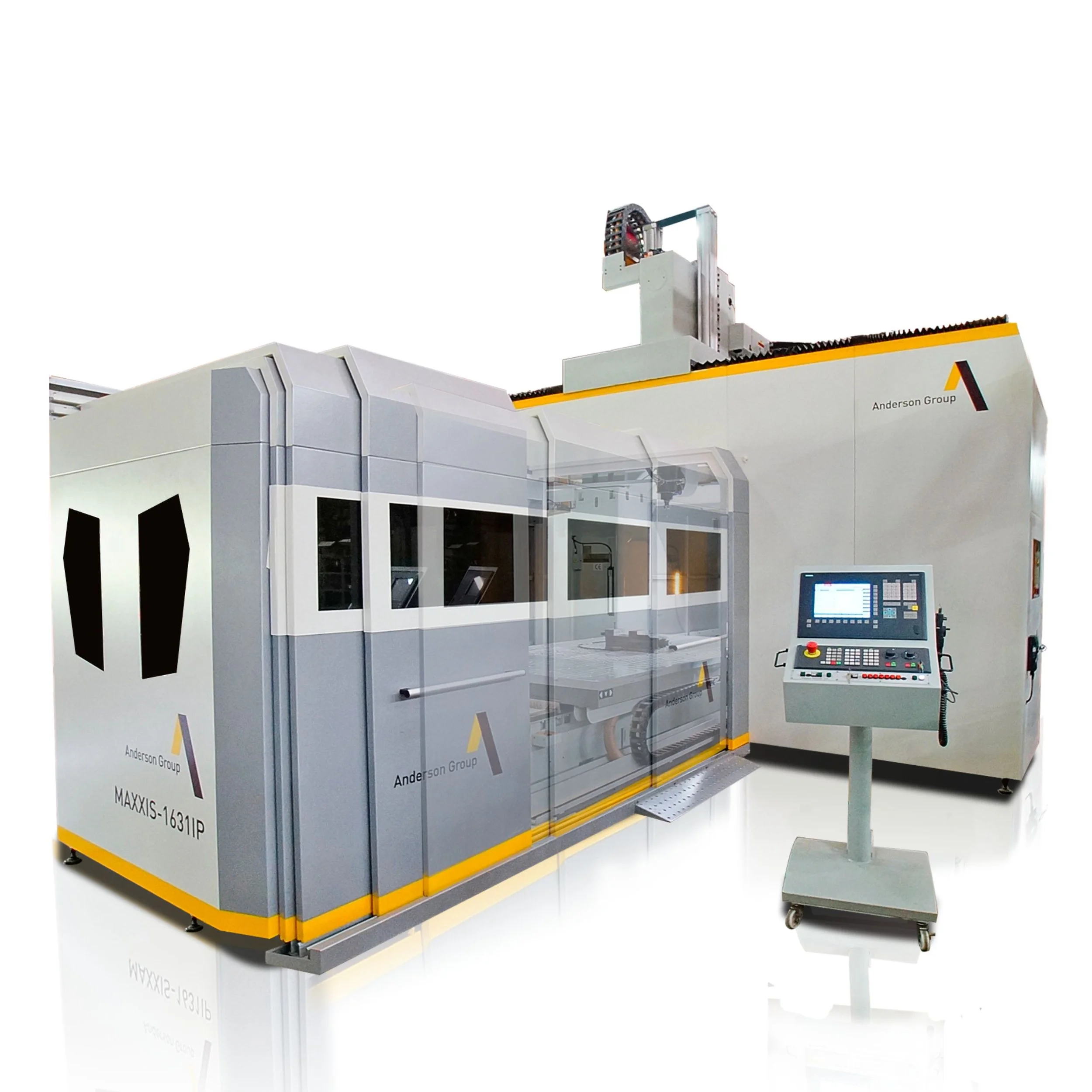

The MAXXIS Series: Unlock Peak 5-Axis Precision & Performance.

The MAXXIS Series redefines 5-axis machining, offering exceptional accuracy and performance for processing plastics, aluminium, and composites. With a rigid fixed bridge and moving table design, it delivers high-speed, heavy-duty 5-axis machining in a compact, accessible form.

Key features:

Highly Rigid Base and Precision Gearbox: Ensures optimal performance.

Anderson Fixed Bridge and Moving Table Design: Offers easy machine access in a compact design.

Webbed Steel Substructure: Remains smooth and rigid during full 5-axis machining.

Advanced 5-Axis CNC Features: Available on both models.

Ethernet Options in CNC Controls: Enables remote technical support.

Workpiece Holding Flexibility: Optional clamping, grid, or manifold vacuum systems.

Industry Standard G-Code: Easy interfacing with major CAD/CAM software.

Additional Options: Including workpiece dimension probing, single and dual zone capabilities, and custom configurations.

Videos & Photos

SPECIFICATIONS:

| MODEL: | MAXXIS-1631IP | |

|---|---|---|

| APPLICATION | Non-Ferrous Metals, Composites | |

| STROKE | X AXIS | 2200 mm |

| Y AXIS | 3700 mm | |

| Z AXIS | 1200 mm | |

| B AXIS | ± 105。 | |

| C AXIS | ± 200。 | |

| TABLE SIZE | 1600 x 3100 mm | |

| MAX FEED SPEED | XY AXIS | 60 m/min |

| Z AXIS | 20 m/min | |

| B,C AXIS | 90。/sec | |

|

ATC HEAD WITH CAROUSEL MAGAZINE

|

NO. OF SPINDLES | 1 |

| TOOL HOLDER SHANK | HSK-63F | |

| NUMBER OF TOOLS | 10 | |

| SPEED | 1,000~21,000 rpm | |

| TOOL DIMENSION | FOR ROUTER BIT(O.D.) | MAX.Ø25mm |

| POWER | ATC ROUTER | 15 kW x1 |

| AIR PRESSURE | 6 kg/cm | |

| NC CONTROLLER | FANUC 31i-MB5 | |

| DIMENSIONS | FLOOR AREA | 5000 x 8000 mm |

| HEIGHT | 5200 mm | |

| WEIGHT | 12000 kg | |